Services

Custom engineered solutions for production, inspection and testing applications

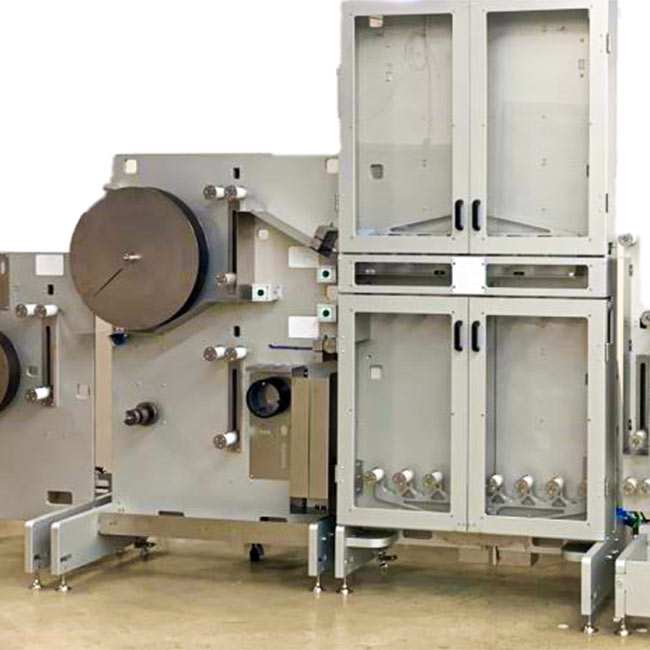

Production at the Point of Assembly

Traditional converting requires raw material inventory at supplier, pre-processing coils offsite, finished inventory in transit, finished inventory onsite, additional quality resources and the ultimate logistical headache of finding out that all that excessive inventory is sometimes actually scrap long after it has been produced.

Production at the point of assembly cuts out all offsite steps streamlining this workflow by creating an elegant, customizable system to handle materials in strip form, producing, and then presenting a steady uninterrupted stream of parts into an automation process. This enables continuous production, removes inefficiencies from the process and provides maximum overall equipment effectiveness.

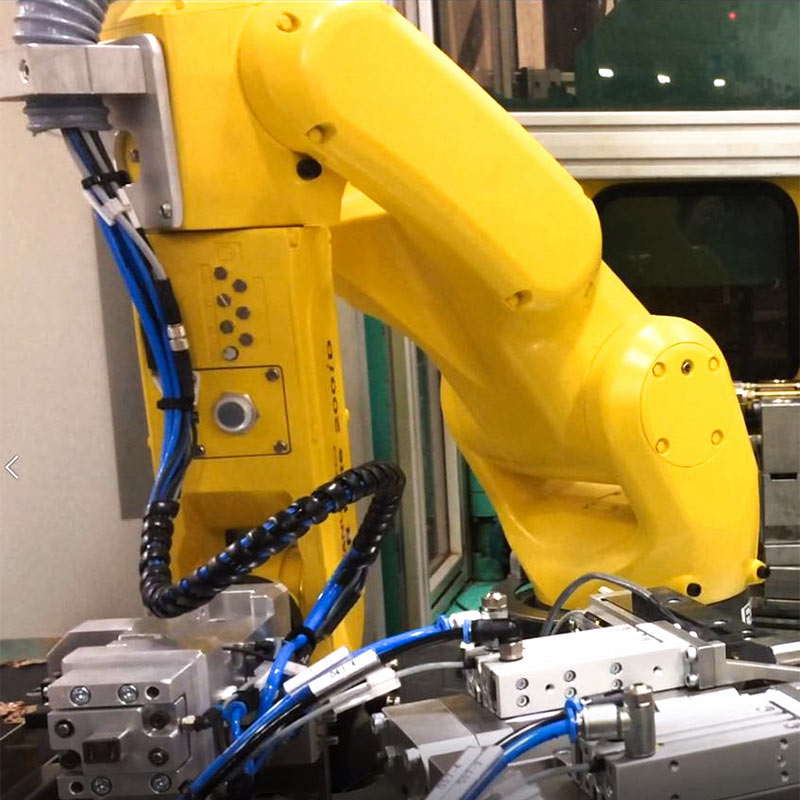

Advanced Robotic & Automation Integration

Jenco builds systems for handling parts and presenting parts into processes from bulk by utilizing robotic vision pick and place. Jenco also applies robotic systems into inspection, testing, and packaging applications.

Jenco’s control packages are regularly tied into larger automation systems, plant wide data collection systems, and equipment such as molding machines and presses.

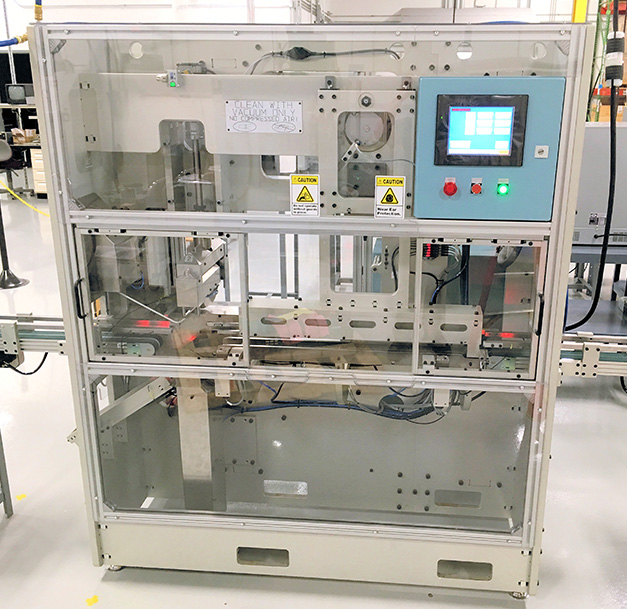

Highly Durable Precision Equipment

Jenco supports customers over a range of capacities in the manufacturing process.

Our services include consulting on new projects through long term support with specialized details, hard tool maintenance and refurbishment required for mature manufacturing processes.

All work is done house. This provides a unique ability to control all details of the project and maintain the discretion of sensitive projects. This means consistent quality and no leaks of IP compromising the value of proprietary processes.

Jenco provides prototyping of products and processes with simplified systems tailored to ensure the successful launch of high-volume automation.

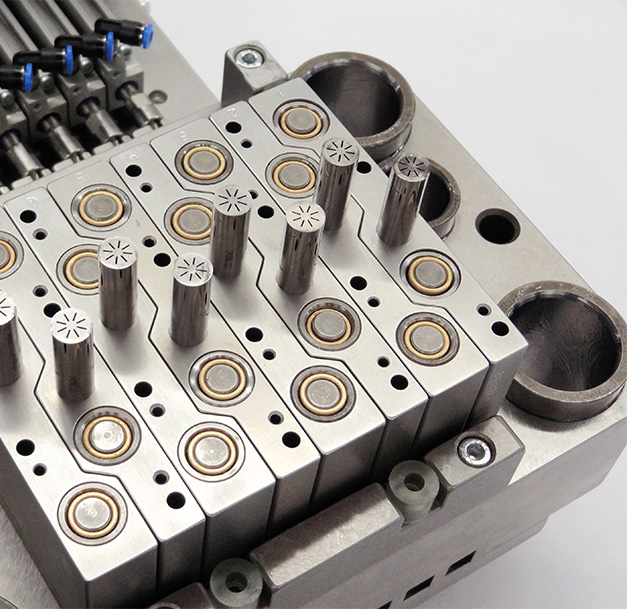

Capabilities

Our in-house metalworking capabilities include the following operations:

- Wire EDM Agie with finishes to 0.2 Ra accuracy to 2 microns

- Sinker EDM AgieCharmilles with finishes to 0.2 Ra accuracy to 2 microns

- Waterjet Omax 55100 capability to process 4’x8’ sheet with high accuracy where required

- CNC capability up to 50”x25”x25”

- Grinding up to 12”x24”

These operations are employed in our internal manufacturing process. We do provide components for applications that require high accuracy and design input as well as other less common capabilities.

Panels, electrical, pneumatic and motion control are also designed, built and programmed in-house.

How Can We Help You?

Let us know what you’re looking for and we’ll let you know how we can help.